Bonding Agents are any products that serve to join pieces or parts of a grave marker together. They range from epoxies to mortars and everything in between. These products more than any of the others walk hand in hand with methods, and help form some of the deepest divisions in the field of cemetery preservation. As with everything else, we will do all we can to weigh out in the most factual manner, these bonding agents with the do no harm principal in mind. Next to cleaning methods and products, the products used to repair and mend grave markers is the most hotly debated issue in the field.

We will examine both the older tried and true agents along with the new comers to the field brought to us through new technologies. We will search out the strengths and flaws in both. And as we have stated concerning methods, we want to keep in mind that a happy medium may have to be struck at the end of the day based on the available knowledge we have at the present time.

Bonding Agents…un-proven or with little to no track record in the field of cemetery preservation.

Pratley Putty, A Potential To Cause Irreversible Permanent Damage

Pratley Industrial Putty or Pratley Standard Setting Putty…There are a slew of Pratley Putty and Pratley products to choose from. And they have all been thrust onto the stage of cemetery preservation in the last year as new bonding agents. The products aren’t new by any means, they’ve been around for over 50 years. But…their use in and for cemetery preservation is so new, its neck snapping. We have been trying to vet this mystery putty for months and are coming up short in most areas of criteria that apply to it being a “do no harm” product and method. And even more puzzling is the lack of explanation, vetting, or track record presented by the notable and respected cemetery conservators in the field who are now pushing this line of products.

We started by contacting the maker to see what they could or would tell us. We always start there out of fairness and for information gathering. We emailed them the following questions.

Our questions

I think the 1st thing we’d like to know is, could you provide us with an MSDS sheet and some sort of product explanation sheet or product instruction sheet?

What else can you tell us about this product? For example: what historic stone work projects has it been used on for repairs? And if so: is there some history or track record you can provide us with on these projects?

What is or was the original intent of this product? Is it meant for repairs to historic stones or something else?

We understand it has great uses for repairing pools and other similar modern works, but that is all we have been able to ascertain. We hope you can respond and help us shed light on the things we have asked above.

Their reply…

There is a short section on the history of Pratley and Pratley Putty on our corporate website

It answers some of his questions regarding Pratley Putty also see attached pictures.

We don’t have any specifics regarding repair of stone monuments etc. although I’m fairly sure it has been used for this.

It was used under water to repair the huge concrete turbine intakes in the mighty Kariba dam wall.

It was used at Sun City to stick down the stone Elephants.

It is used extensively in SA to repair concrete swimming pools.

It has much higher compressive strength than concrete- Of the order of 100Mpa (vs Concrete typically 20-30Mpa)

It has very good uv and weather resistance.

All three of our Putty variants are suitable for Concrete and stone but Pratley Standard setting (original) is most often used.

Novel uses – Underwater identification of lobsters (stick to their shells) for research.

Veterinary Repair of tortoise shell

Sticking tracking transmitters to Pangolin scales for research purposes

Repairing Holed sunken ships

Making Knobs and handles

They did send us the MSDS sheet and an instruction sheet and these two pictures below. The pictures came with no content or context other than being labeled…Pratley 3 and Liberty Monument.

We think the answers above speak for themselves concerning a product that is over 50 years old as to how it applies to historic stone, let alone historic stonework found in cemeteries. The CCUS wants to be more than “pretty sure” it has been used for stone monuments.

We think the answers above speak for themselves concerning a product that is over 50 years old as to how it applies to historic stone, let alone historic stonework found in cemeteries. The CCUS wants to be more than “pretty sure” it has been used for stone monuments.

After we can or cannot establish its use by example or track record, we then look at the products hardness through psi. They claim it has a… much higher compressive strength than concrete- Of the order of 100Mpa (vs Concrete typically 20-30Mpa) Mpa is…metric strength denominated in “mega pascals” and psi is imperial or English for “pounds per square inch”. 20 to 30 Mpa = 3,000 to 4,000 psi. 100% Portland cement is about 3,200 psi., and NHL mortars are much lower depending on sand content ranging in the neighborhood of 750 psi.100 Mpa is 14,503.77 psi. That’s 4 & ½ times stronger than Portland cement. In a field where the LAST thing you want to do is bond or surround old soft historic stone with things like Portland cement, this stuff is absolutely off the charts.

The next thing they gave us that we can look at is… It has very good uv and weather resistance. UV and weather resistance is a desirable thing for any product for outdoor use. But…what is most important is what is in it to make it this way, and in turn, what does that mean for the historic stone? “Weather resistant” often means water proof. This leads to the lack of permeability and wicking issues for water travel in the stone. Anything that may severely interrupt that or stops that process can cause a slew of other damage. We have no other information than what the manufacturer has shared with us. But we can conclude that this is most likely very true if this product is being used to repair pools and leaky boat hulls.

I think one of our members has summed it up best with a very common sense approach after all the fact finding by saying the following…

“Sometimes you have to take a good old common sense approach along with a gut feeling. So let’s look at the box, and the accompanying instructions.”

BOX:

Sets like steel – even under water

Seal metal water tanks, radiators and petrol tanks

mend concrete pool cracks

repair wash basins and toilets

INSTRUCTIONS:

Pratley Company invented epoxy putty

The compressive strength of Pratley Putty exceeds that of concrete

Pratley Putty (original) has been used to float sunken ships as well as repair boats at sea

(Also some of the comments from the box are repeated on the instructions)

CONCLUSIONS:

Regardless of the name, it is a 2 part epoxy.

It is used to seal/patches water tanks, pools, toilets, and boats so it is NOT water permeable. It is therefore a vapor barrier.

It exceeds the compressive strength of concrete, so it is worse than using concrete.

As one conservator put it

“I don’t care who tells me this product is the greatest thing since sliced bread, I personally cannot justify using it on a headstone. (Now if the handle fell off my tuck pointer, I would use this product to fix that.)”

We feel that is well said and does all we can at this point to sum up using Pratley Putty and Pratley products in the field of cemetery preservation. Please re-think what other experts in this field are telling you to use. We wish to thank Pratley for their cooperation and candor and by no means wish to demean their name or their products. We only wish to point out that they are not a good fit for cemetery preservation, and they could pose a high risk of damage to old soft stones.

For more on understanding the stones, stone types and their makeups and how these factors lead us to our conclusions, please visit this link

https://cemeteryconservatorsunitedstandards.org/sources/stone-id/

Bonding Agents…proven and/or known in the field of cemetery preservation

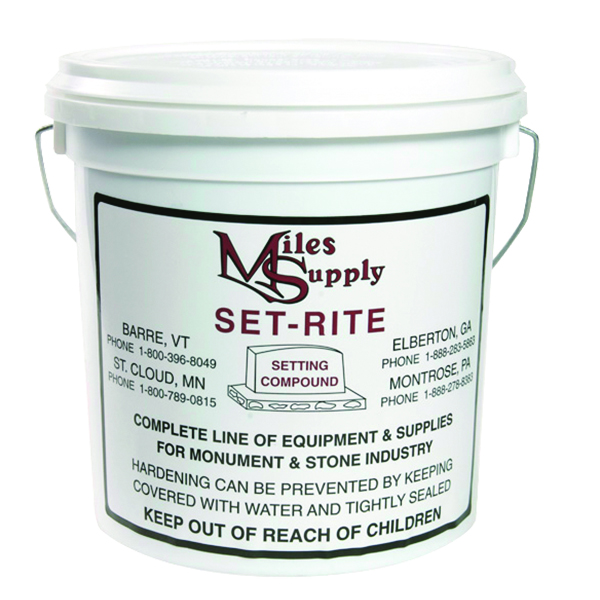

Set – Rite Monument Compound…is very well known among cemetery conservators and monument companies. This compound is a soft clay or plumbers putty like material that is applied between the multi layers of stone in monuments. It is for creating a bond and/or seal between the stone pieces to keep water from directly intruding in between the individual stone pieces. The bond helps stabilize the stone pieces to one another and aids in preventing erosion and movement due to freeze and thaw cycles. This compound was mainly developed for use in conjunction with modern granite monuments.

Granite is harder and much less porous than the older marble, sandstone, or softer schist stones that came along prior to granite use. And that time was long before modern setting compounds as well. During these days when the older marbles and others were in wide use, they were assembled differently. Sometimes a thin layer of lime mortar was used between the pieces for bonding, and other times they were simply assembled using pins and gravity to hold them in place and nothing else. And sometimes you can find some uses of led as that practice came about for granite prior to setting compound development.

“The question becomes one of using a modern technology or a product meant for a harder modern stone like granite, on an older softer stone like marble, as a way to replace an old method, or to improve the old method.”

One very notable conservator in the field has chosen to bridge this gap of new vs old technology, and actively uses and promotes the use of modern setting compounds, like Set-Rite for soft porous historic stone preservation. A majority of other conservators have taken a much harder look at this and will not use it on historic stone.

Setting compound being applied to a historic multi-piece marble monument. This is the type of monument that is soft and porous.

A Break Down of What’s in Set-Rite Setting Compound and How it May Effect Porous Historic Stone

The CCUS asked geologist Don Hilton if he would use his expertise to explain in his view as a geologist, what the possible effects Set-Rite Setting Compound would have on softer porous historic stones such as marble, limestone, sandstone and other such stones. He took a straight forward approach by simply examining the ingredients and information found in the Set-Right MSDS sheet and arranged them by weight/amount most to least.

The Summary

Calcium Carbonate: A fancy name for calcite or limestone. No big deal. It’s what marble is mostly made of.

Linseed Oil Polymer with Soybean Oil: The polymer is the same stuff old linoleum is made of. I’d assume they add the soybean oil to make it more workable. This is part of the glue it possesses. Trouble with this is that it’s organic and will attract biology. Because the other sticky stuff (see below) is a pesticide and small-animal repellent, what you’ll see is non-bug life. Also, if the oils in it mobilize enough to ooze into the pore spaces or between crystals of rocks it will encourage bio-growth and likely stain as it oxidizes. Plus, such oils freeze at about -4 f. While this may seem cold to some, for much of the US that’s a brisk winter morning. Even though most oils shrink when they freeze, they do form crystals that might cause freeze-thaw damage.

Chlorite: A fancy name for micas. Soft mineral, probably added to make the mixture feel slippery before curing and add directional strength once the material is set.

Calcium silicate: Naturally occurring mineral. Even in a powdered form, it is harder than some minerals in pink granites and could scratch polished surfaces.

Polybutene: This stuff also helps glue the rocks together. It’s considered a sticky pesticide and small animal repellent, actually, and can be found in a bunch of different gardening products (as well as lipstick and other cosmetics!). I’d definitely wear protective gloves if handling the stuff!

Quartz: We all know what that is. Even in trace amounts and powdered, it’s much harder than almost all minerals found in any color granites and could cause scratching to polished surfaces.

Were I to use this product, it would be only with non-porous rocks (no old marble or sedimentary rocks like sandstones, or siltstones, probably not slate or limestone, either). So, granites only. And I’d use it only far from exposed surfaces and where it would never show.

Don Hilton April 2nd, 2022

Fitting this Summary into Cemetery Preservation

If you are a modern monument setter, monument company owner, or cemetery conservator, you are most likely familiar with or aware of this product. Because the CCUS focuses on historic grave markers and historic preservation, we will look at this from the perspective of a cemetery conservator and set aside, for the most part this products use and effect on granites and other hard stones.

To Re-cap from the Multi-Piece Basics Section

This product is meant to make an adhesive like bond/seal between modern monument stone pieces such as granite. It is NOT a product for softer porous historic stones like marble, sandstone, shist stones and the like. This product is very oily by nature because it contains linseed oil polymer and soybean oil in order to make it pliable for use and flexible over its life. These oils are organic and can attract biological grown due to that factor and are subject to freeze at -4. And when this product is applied to a soft porous stone like marble, the oils can mobilize enough to ooze into the pores. Most oils shrink when they freeze, but do form crystals, that may/could cause damage during freeze/thaw cycles. This action also dries out the putty like seal and there for makes its use irrelevant. This product is also not meant to be any sort of bonding agent and cannot take the place of a lime mortar binder. If at all possible, you should never unnecessarily apply things to a stone that will work into the pores or between the grains or crystals inside.

The Conclusions Of Conservators In The Field

1…They worry that possible harm or damage could be caused when the porous old stone draws the oils out of the setting compound into itself like a sponge. And because there are no known studies that can address this on one side or the other, these conservators are refusing to use this product on anything but granites.

2…Some conservators have noticed in some cases where this setting compound is used between porous marble, that it appears to have dried out rather quickly compared to its use on granite. Leading them to believe, the porous stone drew out all the malleable ingredients of the setting compound into the porous stone. Again, there have been no exacting studies to bear this out, just the observations of experienced conservators who are noting and documenting what they observe. These observations are why they are refusing to use this product on porous historic stone.

3…These conservators who believe this compound is being rendered useless due to drying out, then worry it could contribute to their work becoming unstable. This could be problematic where safety is concerned, or harmful to the conservator’s reputation at the very least.

4…And finally, these conservators who work in the historic preservation manner, will argue to simply avoid any of these problems by sticking with original historic variations of lime mortar bonding methods.

The CCUS CANNOT condone the use of this monument setting compound for historic soft porous stones. If it is a granite monument that you are reassembling, then you may want to seriously consider using this product. Many of our conservators use it for granite.

For more on understanding the stones, stone types and their makeups and how these factors lead us to our conclusions, please visit this link

https://cemeteryconservatorsunitedstandards.org/sources/stone-id/