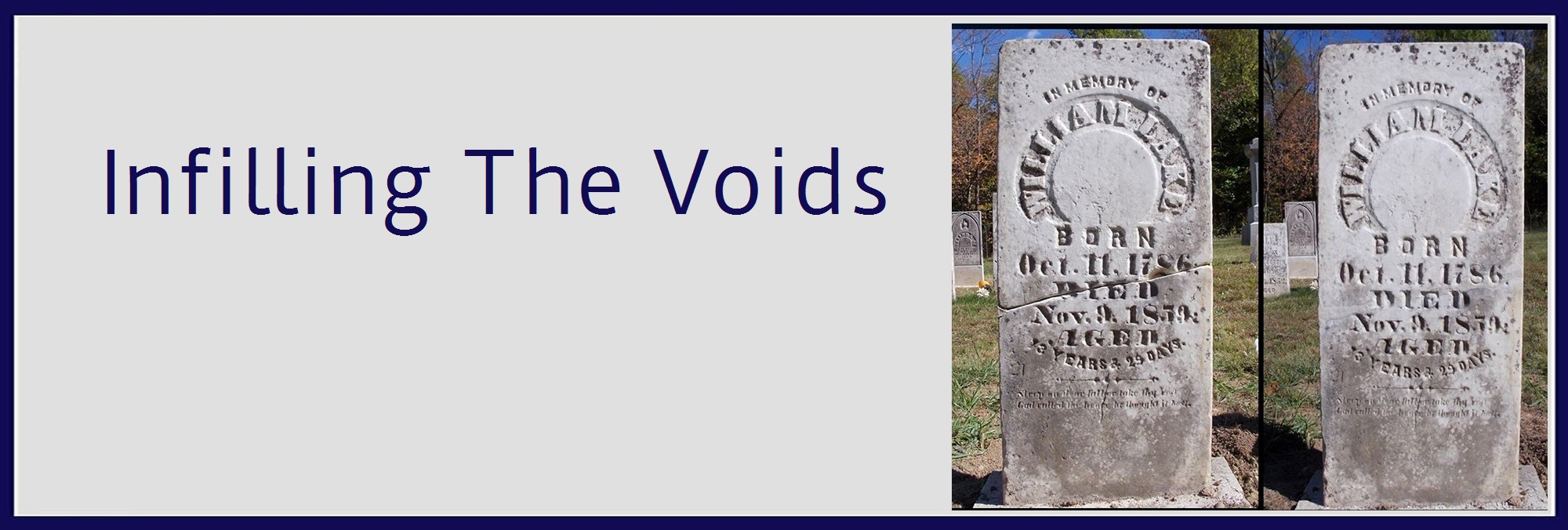

Infill Basics

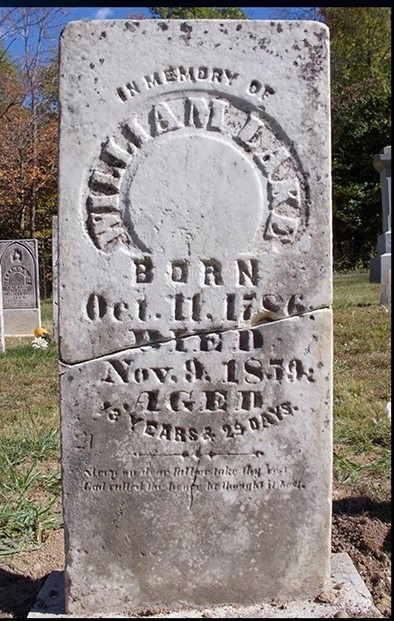

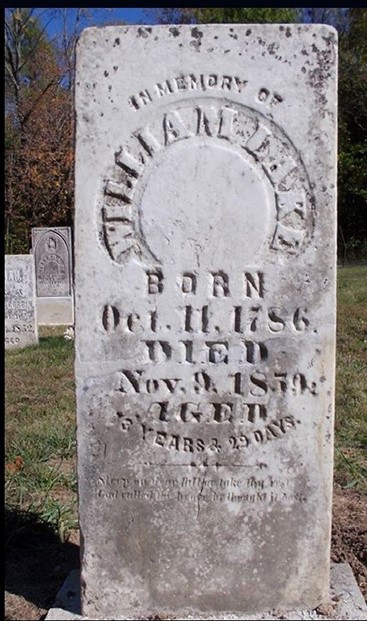

Infill is the process of filling in the gap that remains after a repair has been made to mend a stone. This final step helps to eliminate any open gaps that are left, that may allow excessive water build up that could cause an issue during a freeze/thaw cycle. Infill is a fine mortar that aids the stone in breathing and moisture transfer. In short, it helps to protect the repair that was just made. It is also your finishing touch concerning the aesthetics for the overall look of your final work. The most important part of this procedure is the materials or products used in your infill mix. Color matching is secondary and more a thing of pride in a job well done. Tweaking this to get the most seamless repair is practice, practice, practice. Most preservationists will tell you it’s their biggest challenge. Working at this is ideal for the meticulous person or someone with a history of crafts or finite hobbies. People of these backgrounds seem to thrive with this process. The important thing to remember is, it’s much less about an art contest, and much more about filling in the gap with a proper mortar. So don’t let any of this intimidate you. Be confident and move forward.

VOID FILL/INFILL

By CCUS member Lloyd Collins of Polk Cemetery Savers

This section is intended to describe the methods to fill in the gaps that are left after repairing the headstones with epoxy. This task is also not for impatient people. It takes time, skill, and a knowledge of materials and stone types. Infill color should match the cleaned stone as closely as possible. Since the material can dry up to two or three shades lighter than the wet mix, one should have test blocks with different color amounts per volume. Just attempting to guess the color will not give the results we strive for. In addition you may need different material for different types of stone, thus more color blocks. You must also have a mixture recipe for the different stone types.

After a headstone has been epoxied together, any epoxy that is in the crack that is not holding the stone together has to be removed. This can be done with a small wood chisel and a wooden mallet. This is a very hard task. The epoxy, when cured is brittle and chips like ice. You have to be very careful to remove the epoxy without damaging the stone. Having said that, infill material will not adhere to the hard epoxy, so the crack has to be cleaned so bare stone is available to adhere to the infill. If a chisel is not sufficient to remove the epoxy, you may have to resort to a dremel-like tool with a small diamond blade to scrape off the epoxy down to the stone. It must be done carefully and with small amounts at a time.

After the crack has been cleaned of epoxy, and the color block of correct material has been matched to the stone. It is time to mix a batch of infill material. Check the infill material list for recommended material.

After the material has been mixed, wet the crack with water. This will help the mix adhere to the stone. Using a wooden craft stick, carefully fill the void with the material. Since the material will tend to shrink slightly as it dries, ensure there is enough material to allow for shrinkage. Smooth the material as best as possible. After about two hours revisit the filled-in crack and smooth the material again. If there is engraving to be touched up through the infill material, allow the material to dry for about 12 hours. Using a #2 pencil, lightly pencil in the outline of the letters to be touched up. Using a pointed craft stick, lightly and carefully remove some of the infill so you can see and read the engraving. Let the mix dry for another 12 hours. Using a new craft stick, cut it to match the depth, angle and width of the original engraving. Carefully use this stick to etch out the fill material until the engraving appears similar to the original. You will never get it to match perfectly. In this case close is good. Touch up the infill as needed.

Noncommercial Infill Recipes And Techniques

Feathering Your Infill

By CCUS members Dave & Cindy Nicols Cemetery Preservationists

I used to be a cake decorator, so this is just second nature to me. It just takes a little patience and practice, but in the end, it may not be your cup of tea.

My husband, David, and I served on the Fayette County Cemetery Commission in Indiana for three years, and since the funds were low, we looked for affordable, yet approved methods for our repairs. When you repair a stone with an approved epoxy, make sure the mixture is back from the edges. If it goes to the edges, there won’t be anything for the mortar to adhere to. If this happens, you should take a fine chisel and chip the hardened epoxy away, being very careful not to chip away the stone. Then use water and a soft bristle brush to clear away any residue and powder.

When ready to infill, use a misting bottle and dampen the stone (not dripping wet) so the mortar will stick to it (mist more as you work if it starts getting dry). Using a small thin trowel, push the mortar into the cracks and voids, making sure to fill it in well. You should use gloves, but I like to ‘feel’ what I am doing so I don’t use them. I also tend to use my hands instead of the fine trowel to push the mortar in.

When the cracks and voids are filled to my satisfaction, I use my fingers to feel and make sure it is flush with the surface of the stone. Using a triangular makeup sponge, I get the sponge wet and then squeeze out the excess moisture and then draw it lightly across the mortar and stone, ‘feathering” the finished edge.

Make sure to clean up any ‘extra’ feathering on the stone using a clean makeup sponge. If you are working on a stone other than just white marble, you might want to press a little of the matching stone dust into the mortar after you smooth it with the sponge.

If there are parts of the engraving to be re-carved, I wait just a short while and then use bamboo crock pot pics, popsicle sticks or pottery tools to recreate the lettering/art.

Mortar Mix for Infill

1-2 parts White Portland Cement

4-5 parts Natural Hydraulic Lime (3.5)

7 parts Stone Dust (Marble, Limestone, Sandstone, etc. matching what you are infilling)

Add clean water a little at a time mixing well, you want it to be fairly thick to use.

A Midwestern Infill Recipe

¾ part…hydrated building lime type S

¼ part…White Portland cement

2 parts…white marble dust, course or fine depending on the size of void gap

Moisten the stone so it does not draw moisture from your mortar. Big voids need more than one lift to fill and will require small pieces. This mix will result in a finish that is bright white so…you need a very soft brush to take back a little surface mortar after it sets just a little. That will expose the aggregate and give you better color match immediately. You need to hydrate with mist often and cover. In dry weather a gunny sack works fairly well but you need not let it dry out. Protect and hydrate frequently with mist for 5 days. Hot dry weather is the worst and may take more. Cool 50’s and 40″s at night helps slow down the cure which is good. Proper masonry in exaggerated weather is a challenge. Ratios of mix change with that weather.

3.5 And white marble aggregate is a good summer mix but again one needs to baby it along. A tablet stone is bombarded by elements from all sides. Think of your wet thumb sticking in the air and how it reacts to the elements. A stone the same way. Comfortable mason is comfortable mortar.

A New England Infill Recipe

1 part NHL (3.5 or 5)

3 parts marble dust slurry (dried)

Not practical for everyone unless you have a wet saw. But if you do, the left over slurry when dried is a very fine marble dust powder

An Oregon Infill Recipe

However, recommended material used to infill headstones varies by State and National Organizations. Check your State and/or local requirements for their list of setting materials.

For instance, the material shown below is specified for use in Oregon.

Mortar for Filling Void Patch Mix

2 parts White Portland Cement (recommended ASTM C-150. Type 1)

4 parts Hydrated Lime (recommended ASTM 207, Type S)

7 parts Stone dust and grit

Clean water, use sparingly, mixture should be very stiff, Use different colors of powdered grout to color

the mortar mix for a decent color match

There is a commercial product available special ordered from Home Depot, that with added lime, closely matches Oregons’ recommendation. We have received permission to use this.

Quikrete White Glass Block Mortar Mix with 3 parts added hydrated lime. This type “S” mortar mixture consists of 2 parts White Portland Cement, 1 part lime and 9 parts fine white sand. (12 parts) By adding the extra lime, three extra parts, the mixture is very similar to the state recommended mix.

Mix ratio… add slightly less than1/2 cup of hydrated lime to two cups of the Quikrete mortar mix.

DECEMBER 31, 2017 – CEMETERY CONSERVATORS FOR UNITED STANDARDS

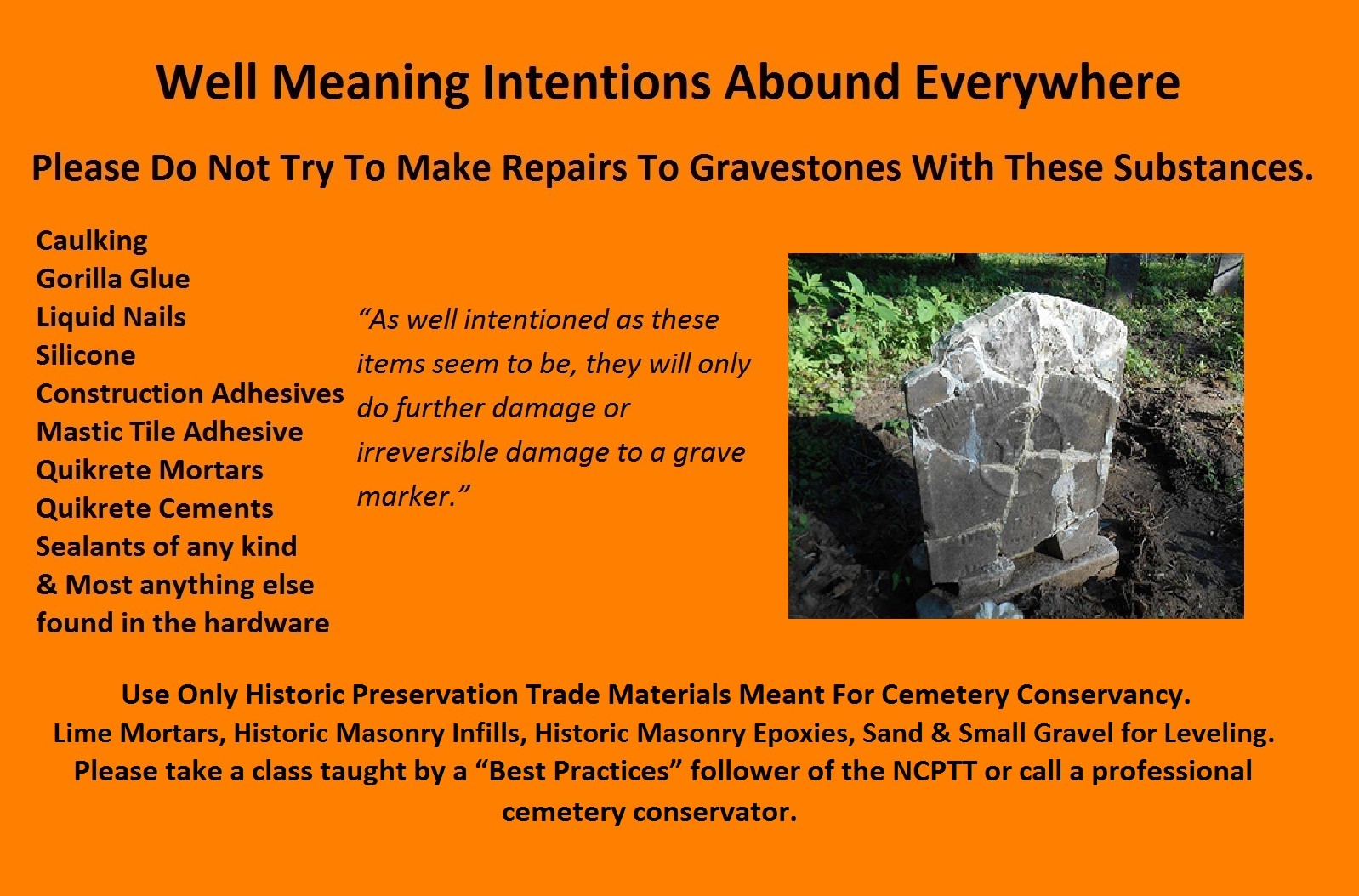

Don't Repair With

Now that we have walked you through the “do no harm” methods for infill, we will explain the harmful methods some have used in their stead.

Don’t Repair With – is our section that explains the harm that can be done to tombstones and monuments when they are repaired with common building supply store materials. Again, good intentions are always admirable, but also very destructive and permanent most of the time. We hope that by addressing these notions and theories of hardware store repairs, we can show you the best way to achieve your restoration goals. These basic techniques and materials are quite simple in reality. You just have to follow the instructions and buy the right materials for the job. Because it should always be about what is best for the cemetery. It should never be about what is the easiest thing to do or buy. You will find more about good repair methods and products under BASIC STANDARDS and PRODUCTS USED.

Below is a list of things you shouldn’t use to repair grave markers. This list is much longer than the list of what you should use.

It is better to do nothing at all than to do something harmful. This is very hard for many people to understand, because they let their want to do something, over-ride the need to do it damage free.

These are goo’s, glues, and caulking types of various sorts. None of these will last more than a couple of years. Please don’t be fooled by some claim made on the package or by some suggestion from the store clerk. As we all know, wild claims abound by manufacturers and those selling products. Your first clue should be the cheap price. Since when has cheap and convenient ever equaled quality in any item?

Eventual short-term failure should be a concern for the following reasons. First, the stone presents a safety hazard to anyone who visits the cemetery when it fails. Second, the toppling stone will only result in further damage. Third, removing the failed repair material will damage the stone further or become impossible to remove. Is possibly causing injury and destruction worth using poor repair methods?

Please don’t add to an already bad situation by doing things that will cause greater safety hazards.

Take your time, they’ve been here over a 100 years and aren’t going anywhere.

The stone on the left appears to be a sandstone or siltstone with delamination issues that cause vertical fissures in the stone. The caulking will not discontinue this splitting. It will only serve to interrupt how the stone breaths. The stone to the right is a mortise and tenon type with a large slot in the base. Caulking won’t seal the two stones back together like you may believe. It will simply trap water in the slot.

Caulking type products in a tube do more harm than good. If you do get it to stick, it’s not going to last long. But the damaging part about using caulk is the vapor barrier it makes. Caulking is meant as a sealant. Sealants don’t breath. Stones that don’t breath retain water. Stones that retain water will rot and decay in a warm climate, and freeze and break in a cold climate.

Then you have the mess that makes the inscription no longer legible and a damaging thing to remove. Is this how you really want your repair to look?

Repairs done with concrete and modern mortars are some of the most damaging. We address this in further detail under…Don’t Use Concrete. But because modern concrete and mortars are among the first choices by so many, we will mention them here also. Concrete is a bad permanent solution to an otherwise less harmful method. Here is one such example that combines a harmful material with a poorly thought out repair method.

This tombstone doesn’t have a square angle in any direction or side. It seems to have been quickly hodge-podged together with a combination of modern mortar and some sort of putty product. This ill thought out repair may be permanent for this stone. At the very least it will take a professional with some skill to undo this situation. Examples like this are why we stress taking your time and thinking through your methods.

These stones are engraved pieces of priceless history that no one individual owns. They belong to all of us and to future generations. Please preserve them with no harm dignity, hire a professional, or please leave them alone.

Other areas of interest that pertain to infill

For more discussions that may have a bearing on tablet setting methods, mouse over PRO VS CON and choose Bonding Issues and Method Issues. You may also find the other categories under PRO VS CON helpful as well.

This section is here to weigh out the many “Pros VS Cons” that seem to exist in this relatively young field known as the cemetery preservation and restoration. A young field born out of the need and want to maintain the memorials left us in cemeteries. Maintaining things from the past has been around almost as long as the past itself. Art, documents, books, buildings, and now cemeteries. After the desire to save these things is met, then begins the how to save them, through what means and with which forms of maintenance. This quickly becomes a much clouded issue for many. We hope to lift this fog with some simple fact based thoughts and principals. Our cornerstone or main pillar for doing this will be a thing called, “Do No Harm”.

This section has two main goals. One is to lay out and examine the field itself and all of its controversial issues, problems, and divisions. The second main goal of this section is to lay out the said issues involving methods, techniques, and products, and run them through the list of 6 or more questions below. This is where you find the meat of the discussion before it is weighed out with these questions.

We are addressing as many of these issues as we can at this time with the following subcategories in this section. “The Field In General” subcategory addresses the overall methodology of the field itself. Other subcategories such as Cleaning and Bonding Agents, and others to be added, will address more specific methods and products.

These are the 6 standard questions we will ask of all methods, techniques, and products suggested or discussed on The Cemetery Conservators For United Standards website. Additional questions may be asked pertaining to a given subject depending on the need to ask them based on the subject. You will find the completed version per product and/or method under SOURCES…Pro VS Con Results.

1…MSDS… based on the MSDS recommendations. (Scale of 1 to 10) 1 being the most invasive or highest risk to a person’s health & safety. And 10 being the least invasive or lowest risk to a person’s health & safety.

2…Testing…has it been tested? (Scale of 1 to 10) 1 being the lowest # of testing done. And 10 being highest # of testing performed.

3…Longevity & Performance… based on reliable reports concerning how long & well the product holds up. (Scale of 1 to 10) 1 being the shortest longevity & lowest performance. And 10 being the most longevity & best performance.

4…Track Record & Wide Spread Use…How well has this substance or product in this technique held up over the years & how many places has it been used? (Scale of 1 to 10) 1 being the worst track record, least widely used, & least places used. And 10 being best track record, most wide spread use, & most places used.

5…Permanence…is the substance or product in this technique, reversible or nonreversible? (Scale of 1 to 10) 1 being the lowest possibility of reversal. And10 being the highest possibility of reversal.

6…Cost & Training…how expensive is the product & is there specified training required & what is its cost? (Scale of 1 to 10) 1 being highest cost & most training. And 10 being lowest cost & least training.

TOOLS & SUPPLIES…things we suggest to better aid in your cemetery preservation work can be found here.

TECHNICAL…is the place where we house all information for products used and has Product Explanations, Product Information Sheets, and MSDS

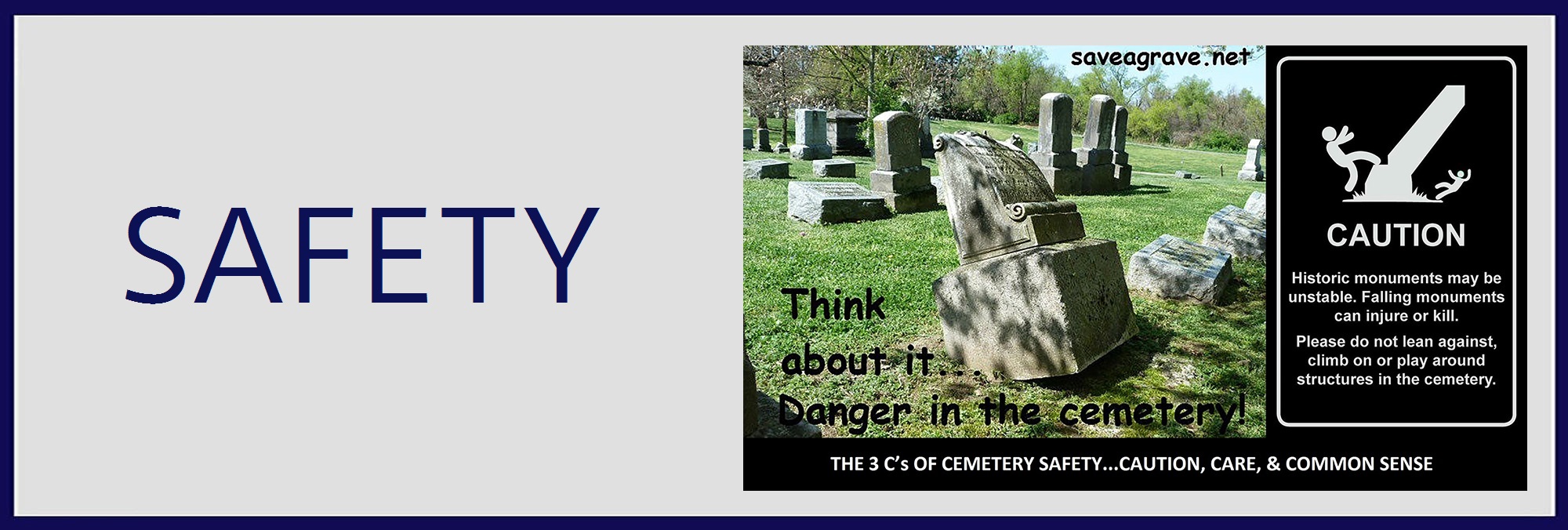

SAFETY…is always an important place you should visit at every step along the way

SAFETY – a place for all safety related issues found in cemeteries and in the preservation of cemeteries. Every year people are killed due to unstable stonework in our cemeteries. Over time many of these monuments begin to lean and teeter. And unsuspecting visitors are crushed because they disturbed one of these loose monuments. We wish to remind people of this situation and caution them from such tragedies. Safety is also equally important for those who choose to do some sort of restoration work. The hazards can range from a pinched finger to being killed by a large stone. I can say all of our members take safety very seriously and make it our constant number one priority in everything we do. We please ask that you do the same. This section will try to address this issue as much as possible. Let’s all be safe out there in all that we do.

This is where you will find the latest video links to cemetery preservation and restoration. There are many great videos from both professional organization and CCUS members. We will constantly add new media as it becomes available. Mouse over VIDEO and choose an area of interest. You will find one of the six areas below to view.

Cleaning – the best ways to clean with no harm.

Hoist Work – lifting stones with a hoist type system.

Repair Work – putting the broken pieces back together again.

General Field Work – a collection of misc. preservation work.

Good Preservation – what good preservation looks like.

Bad Preservation – what bad preservation looks like.

ARCHIVES…is where we house downloadable pdf’s and FREE cemetery preservation related images for you to use. We have jam packed this ever expanding library with pdf’s on important cemetery related issues. We wanted you to have a place where you could easily view, print, or download important information. We encourage you to share it with other individuals or groups you may know that are interested. There is no such thing as too much cemetery awareness.