Basic Repairs is our section that walks you through repairs to tablet style grave markers. Broken tablets are some of the most common things found and asked about. This section will begin with simple single breaks and work up to multiple breaks that can resemble jigsaw puzzles. Many of our members have become quite skilled in this area. It did not happen overnight. It took lots of practice and patients, so don’t be overwhelmed. Because they all started out just like you with the very basics. This section will also show you these repairs being made in two different settings. In the field or outdoors, and indoors. Repair work in the field is the most common and practical setting for many reasons due to logistics and permissions. Repairs made indoors have the advantage of controlled conditions and the convenience of a workshop setting.

The basic repairs covered in this section are methods that should be taught to you in a hands on manner through a workshop or class. They can be much more complicated than we are able to express on this website. This section is designed as an introductory overview only.

Because this section touches on what we are terming as “Bonding Agents”, meaning any product or material used to join grave markers together. These will also be addressed in other sections of the website under PRO VS CON and under SOURCES…Pro VS Con Results. Please go to these sections for a more in-depth look and understanding before attempting any of these procedures.

The following is a great tutorial on repairing broken tablets, mainly marble tablets, with a focus on repairing them with an approved epoxy. We feel this is a great place to start when it comes to repairing or mending broken tablets. More on this procedure and different ways to use epoxy products that are widely accepted across the rest of the country, will be addressed below this article.

REPAIRING BROKEN HEADSTONES

By CCUS members Lloyd Collins of Polk Cemetery Savers and Mark Morton of Gravestone Guardians of Ohio

Headstones in most of the cemeteries across the country have either been set in the ground, in slotted bases, and some rare cases in concrete. Over time, the ground has shifted, rodents have burrowed under the bases, or animals, using them as scratch poles, have pushed the headstones off of vertical or broken them off at or above ground level. Vandals have also caused damage by pushing the headstones over or breaking them in pieces. Whatever the reason, some of the headstones are broken, sometimes in many pieces. These headstones are predominately of a “Tablet’ design. It is to the benefit of these headstones to be cleaned, repaired, and reset so they stand vertical. The headstone can then shed water and breathe properly.

The repair of broken headstones is a task that should not be taken lightly. This task takes patience, skill, time, and the use of the proper tools and materials. Few headstones can be repaired in a day. Most will take days and some will take weeks before the headstone can be repaired with epoxy, voids filled, engraving restored through the infill, and reset to stand straight on its’ own in the cemetery. Every broken headstone is different and although the repair methods may be the same, the series of tasks will be different. This standard will attempt to provide basic methods and define a series of tasks that will be needed to repair two types of broken tablet headstones that are in two pieces, and a tablet headstone that is broken into many pieces that may or may not be attached to a slotted base. If the base of the headstone is still in its’ slotted base, but the top is in several pieces, the top will have to be repaired first and then attached to the bottom section.

An introductory overview from a cemetery preservation class setting

Tablets in the condition like the one to the left are quite common. This is a white marble tablet that fits into a slotted base and has a single break. This tombstone was chosen to demonstrate how to repair a single break at a cemetery preservation class.

PRECAUTIONS AND OBSERVATIONS

As with any work done on headstones, the stone must be carefully inspected before any work is started. Headstones, even though they are made of stone, are very fragile. Over the years they may have developed damage from the environment. This damage could include delamination, stress cracks, and areas where water has infiltrated the stone and frozen causing larger cracks or other broken areas. Attempt to locate all of the broken pieces, no matter how small.

After this stone was evaluated and deemed to have no serious delamination or issues of sugaring, it was carefully excavated for cleaning and prep. It was cleaned with D/2 and left to dry thoroughly in the sun. Epoxy should only be applied to dry stones. The edges at the break were gently wire brushed to remove any leftover loose dirt that would adversely affect the epoxy bond. Mendable edges like these are the ONLY areas you should ever use a wire brush on.

Now we are ready to apply the epoxy. This stone was mended with a 2 part epoxy meant for this type of preservation. Our method here was to apply a continuous line of epoxy down the center of the break, staying away from the edges, but making sure we met all contact points. You don’t want to smear it on the outer face of the stone. Issues like this are best explained at a hands on class. Epoxies have strong chemical compounds, so always wear gloves when handling them. And mix the epoxy according to the directions on the container.

After the epoxy has been applied we are ready to clamp it together. The surest way to guarantee a close as possible fit, is to dry fit the stone together first. This will tell you where your contact points are and show you how clean the break actually is. You will also be able to see where any stone loss has occurred. This will be very important to discover when you begin the infill process and also to judge the overall stability of the repaired stone when finished. The infill process will be covered further down in this section.

The following are pictures and examples of the types of broken headstones that this standard will cover in greater detail. Both in the field and in a controlled environment and by an experienced group of conservators.

A headstone broken into two pieces with bottom set in a slotted base, and a headstone that was broken into two pieces and no longer attached to its’ slotted base.

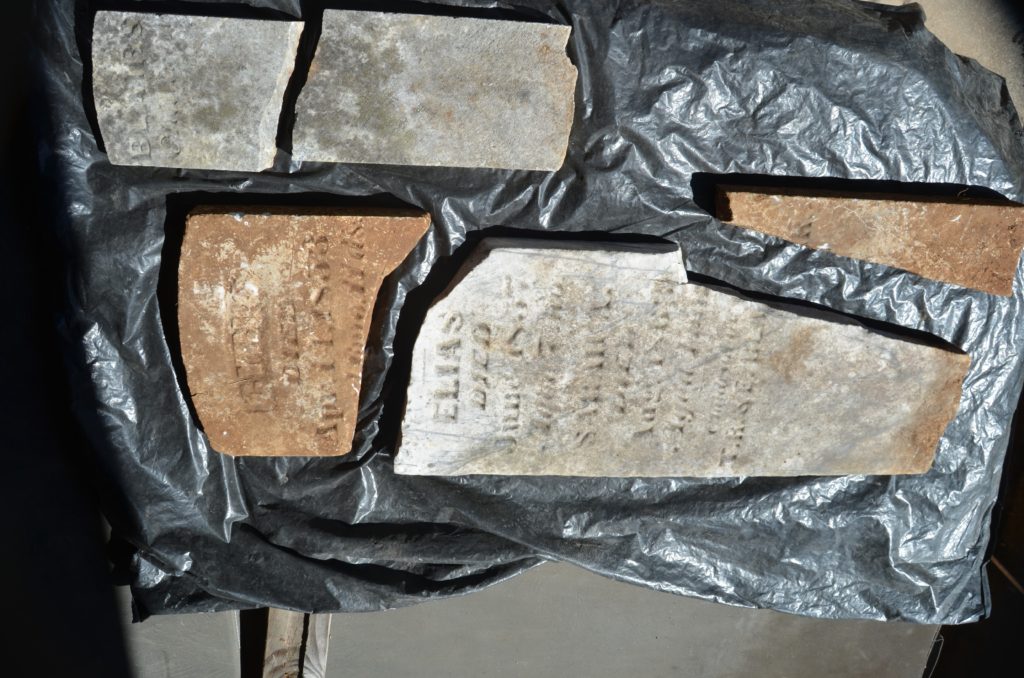

These multiple breaks consist of a headstone that was broken into three pieces, no longer in a slotted base and a footstone in two pieces.

These three broken headstones are typically what you will find in cemeteries. There may be others and you will have to modify repair methods accordingly.

PRECAUTIONS AND OBSERVATIONS

As with any work done on headstones, the stone must be carefully inspected before any work is started. Headstones, even though they are made of stone, are very fragile. Over the years they may have developed damage from the environment. This damage could include delamination, stress cracks, and areas where water has infiltrated the stone and frozen causing larger cracks or other broken areas. Attempt to locate all of the broken pieces, no matter how small.

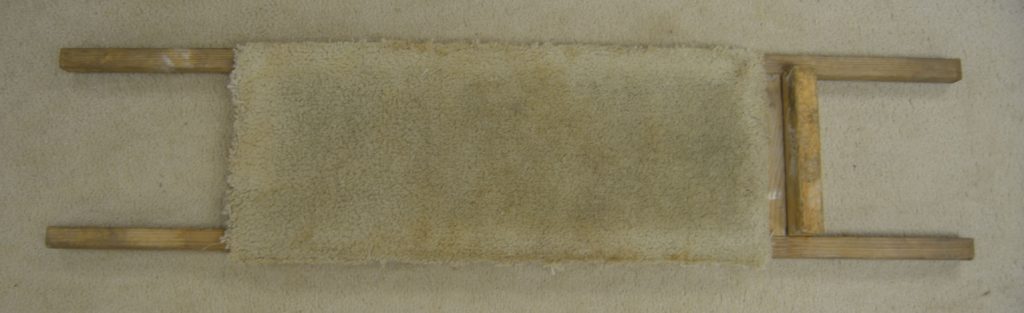

Before moving the broken headstone and parts, ensure it is structurally supported to prevent any new damage. I use a wooden platform that allows the headstone to lie on a carpet pad. The stone is loosely strapped to the platform and two people can lift and move the headstone without damage.

ASSEMBLING THE PIECES

Work table

Whether you repair the headstone in the field or take it to an enclosed shop, you must have a stable work table and a tarp to cover it. The table should be made of 5/8 or 3/4 inch exterior plywood. It can be placed on two saw horses and screwed in place. The table should be level as possible but absolutely must be flat. No warps are allowed. A covering of heavy plastic should be used over the plywood. Stretch it and staple it down. This will prevent any epoxy from sticking to the wood. In some cases a raised platform may be needed to get access to the bottom of the headstone and for enhanced clamping. This is accomplished easily by using 1 1/2 angle iron braces and 4 X 4 spacers.

A benefit of a raised platform is that it allows for the clamping of the outside edges of the headstone to the angle braces.

The headstone must be aligned properly and the stone should be flat so the faces of the broken pieces align properly. Small pieces of plastic should be placed at the broken seams to prevent epoxy from sticking to the angle braces. Another benefit of this method is the capability to turn the epoxied headstone on its’ side to clean excess epoxy from the back before it cures.

It must be clamped properly to allow it to be turned on its’ side, as in the picture above. You may have to epoxy some pieces together on a flat table before you use a raised platform. Case in point…The lower left bottom of the pictured headstone. The small piece was epoxied on the flat table.

Whichever support table method you choose, you must ensure proper alignment of the headstone pieces before epoxying them together.

Assembly

Prepare to assemble the “puzzle”. Spread out the pieces on the flat work table. Be careful not to damage the plastic cover. Fit the pieces together. After the pieces are fitted together you will be able to decide which pieces to epoxy together first and where you will need infill. If you have found all of the pieces or you have decided to fill larger voids, you are ready to clean the parts.

CLEANING THE PIECES

For this repair task you will be cleaning a broken headstone. General cleaning practices In CCUS Basic Standards…Cleaning, cannot be closely followed at the edges. Cleaning the edges of a broken headstone takes patience, elbow grease, and special brushes. Brushes should be small, like oversize toothbrushes. You may have to search for them. A small grout brush and a firm toothbrush should be all that is needed. The broken stone must be carefully cleaned with special care at the broken edges. The edges are incredibly fragile. A simple brushing can break off small pieces of an otherwise sharp edge. All foreign material must be removed from the broken areas. Especially difficult to remove is algae. It will have infiltrated into the stone. Use an approved biocide to kill the algae. Brush it on with a small paint brush and let it do its’ work. This may take several days or longer. Carefully remove the dirt and environmental grime from the broken areas. If you see stress cracks in the broken area, you must try to clean out the crack. You may have to scrape out the crack. Leaving dirt in a crack may cause later breakage if any plant life can take root in the dirt. The rest of the stone can be cleaned now. Be careful near the broken edges. Rinse thoroughly and ensure no cleaning material remains on the stone. Let the stone parts dry thoroughly.

EPOXYING THE PIECES TOGETHER

Now that all of the inspections and preparations are finished, you are ready to epoxy pieces together. There are two types of broken headstones with the bottom still in the slotted base. The first is one where the bottom section provides sufficient support for the top without using external bracing. See the next two pictures.

Broken headstone with bottom section still in the slotted base, “clamp supported repair”.

For this type use the angle braces and clamp them to align the top to the bottom of the headstone. Ensure the edges and the faces of the headstone are aligned. Make a test fit before you epoxy the pieces together. This will allow you to see where the epoxy should be placed and ensure proper alignment of the broken piece.

Use one of the knife grade epoxies under PRODUCTS USED…Epoxies. Thoroughly mix a batch per the manufacturers’ directions. If you think you have mixed it enough, mix it for a couple more minutes. Spread a layer of epoxy down the middle of the broken seam using a wooden craft stick. Use the epoxy sparingly but ensure all crevasses in the break have epoxy spread into them. It may be necessary to spread epoxy on the other section also. The test fit should have determined the need for this. If you put too much epoxy on the broken pieces the weight of the stone will push it out. It will have to be cleaned off before it cures. The trick is to put just enough epoxy to get a secure bond throughout the length of the break without it being pushed out. The rest of the repaired crack will be infilled to match the stone. A perfect match will leave about 1/4 inch deep crack to be infilled. Let the epoxy cure based on the manufacturers’ recommendations for the temperature. See the section BASIC STANDARDS…Infill.

Broken headstone with bottom section still in the slotted base, “brace supported repair”.

The second type of broken headstone is where the bottom section will not provide sufficient support for the top while the epoxy cures without using external bracing. The top of the headstone is much larger than the remaining piece in the slotted base.

For this type use the angle braces and clamp them to the bottom of the headstone still in the base. Test fit to ensure the edges and the faces of the headstone are aligned. Clamp as necessary. The angle braces will help ensure the edges and faces are aligned. Place the external braces in the location they are needed. They can be moved slightly after the pieces have been epoxied together. Make another test fit before you epoxy the pieces together. This will allow you to see where the epoxy should be placed and ensure proper alignment of the broken piece.

As in the previous section, use one of the knife grade epoxies under PRODUCTS USED…Epoxies. Thoroughly mix a batch per the manufacturers’ directions. Spread a bead of epoxy down the middle of the broken seam using a wooden craft stick. Use the epoxy sparingly but ensure all crevasses in the break have epoxy spread into them. It may be necessary to spread epoxy on the other section also. The test fit should have determined the need for this. If you put too much epoxy on the broken pieces the weight of the stone will push it out. It will have to be cleaned off before it cures. The trick is to put just enough epoxy to get a secure bond throughout the length of the break without it being pushed out. The rest of the repaired crack will be infilled to match the stone. A perfect match will leave about 1/4 inch deep crack to be infilled. Ensure the pieces of the stone are aligned. Support the repaired headstone with the external braces. Clamp the braces in place. Ensure they do not move. Let the epoxy cure based on the manufactures’ recommendations for the temperature. See the section BASIC STANDARDS…Infill.

This is the second type of broken headstone that is in two pieces. For some reason it is no longer mortared in its’ slotted base. Clean carefully per the previous section, ‘Cleaning the Pieces’. This stone had a lot of algae but luckily none in the broken areas. There was a lot of staining on the stone. D/2 was used to clean the stone and then a second coat was sprayed on and left for several days. The stone was cleaned again and left to dry. This type of broken stone can use either a flat table or a raised platform. It should be your choice based on the headstone. I used a flat table for this repair. It is important to do an alignment fit with any stone you are repairing. This stone needed slight shimming to align the face of the two pieces. When you are sure of the alignment you may epoxy the two pieces together using the procedures previously described. Use whatever clamping is necessary to ensure alignment. Do not remove the clamps until the epoxy has set.

Epoxying and clamping the two pieces

As in the previous section, use one of the knife grade epoxies under PRODUCTS USED…Epoxies. Thoroughly mix a batch per the manufacturers’ directions. Spread a bead of epoxy down the middle of the broken seam using a wooden craft stick. Use the epoxy sparingly but ensure all crevasses in the break have epoxy spread into them. It may be necessary to spread epoxy on the other section also. The test fit should have determined the need for this. If you put too much epoxy on the broken pieces the weight of the stone will push it out. It will have to be cleaned off before it cures. The trick is to put just enough epoxy to get a secure bond throughout the length of the break without it being pushed out. The rest of the repaired crack will be infilled to match the stone. A perfect match will leave about 1/4 inch deep crack to be infilled. Ensure the pieces of the stone are aligned. Support the repaired headstone with the external braces. Clamp the braces in place. Ensure they do not move. Let the epoxy cure based on the manufactures’ recommendations for the temperature. See the section BASIC STANDARDS…Infill.

The picture above is the finished headstone. The voids were filled with a mixture of white Portland Cement, lime, fine white sand, and colored to closely match the stone. Your void fill mixture may be different but some have to follow the state guidelines. As you can see from the picture, some of the staining was not removed. D/2 will work over time so hopefully more of the stain will disappear. The void fill was left to cure for two weeks and then the stone was returned to the cemetery and placed into its’ slotted base.

Headstone broken in multiple pieces

This headstone and associated footstone were found inside a small concrete-curbed enclosure. Two of the pieces were buried and were found by probing the area.

Headstone epoxied with rough infill. Infill was smoothed out before the mixture cured and after about two weeks, the stone was returned to the cemetery.

For broken headstones like this, the cleaning procedure is the same. Be careful! After cleaning do a test fit to determine what clamping you need to ensure the parts line up properly. This type of break requires two straight edges, one on each side. Angle braces are perfect for this type of repair. With clamps in place on the largest section, the two smaller pieces can be aligned and epoxied and clamped, one at a time. After the epoxy cures the infill can be added to finish the repair.

Repaired headstone and foot stone returned to the concrete enclosure. Repaired, plumbed, and standing tall.

RECOMMENDED TOOLS AND MATERIAL

Below is a list of possible tools you may need when repairing headstones:

- Tarp

- Small Brushes

- Angle Braces

- Plastic Scrapers

- 24-Inch Level

- Work Table

- Sponge

- 1×2 Wooden Straight Edges

- Mixing Pan

- Saw Horses

- Level

- Orvus Soap

- Approved Epoxy

- Craft Sticks

- Rubber Gloves

- Compressed Air

- Sprayer w/Water

- Clamps w/Plastic Pads

- Denatured Alcohol

- D/2

February 2, 2017 – CEMETERY CONSERVATORS FOR UNITED STANDARDS

Further Information About Epoxy Methods

We recommend these epoxies…Akemi Akepox 2030, Tenax Domo 10, Tenax Rivo 50, and Rivo 15 are good choices

There are three basic ways to apply epoxy when mending a broken tablet. First is to spot the epoxy on the stone at several contact points along the break. This is the most minimalist way. The second is to form a thin line down the center of the break leaving the edges free of epoxy. This is the middle of the road way. The third way is to coat the entire break surface with epoxy from one edge to the other. This is the extreme way to epoxy. At the moment many reputable conservators in the field can be found using and/or teaching all three methods. So all three methods will continue to be addressed here.

Recently epoxy use has come under some fire from members in the field. This has been for reasons such as failure or non-permeability. The claims of failure in this case are quite simply that the epoxy in question has lost its bond. Permeability…meaning in this case the allowance of water or moisture to travel uninterrupted through the stone. Non-permeability is when water or moisture flow are cut off or interrupted. These issues or claims by others in the field are addressed under PRO VS CON…Bonding Agents. Or under SOURCES…Pro VS Con Results. Please go to these sections for a more in-depth look and understanding before attempting any of these procedures.

An alternative to epoxy use for mending stones such as tablet breaks, comes in the form of new mortar products. These new mortar products appear to be hybrid mortars with bonding capabilities. They are relative newcomers when compared to epoxies and should be strongly considered. Until we can more thoroughly examine and understand these new products, the most we can do is merely mention them. We hope to have a much better understanding of these new mortar products over the upcoming year, and hope to be able to safely add them to our collection of bonding agents and repair products.

December 23, 2017 – CEMETERY CONSERVATORS FOR UNITED STANDARDS